Voltage: 600/1000V

Conductor material: Aluminum/Aluminium alloy

Number of Conductors: 1-5 core

Conductor Strand: 7

Armor: Aluminum or Steel

Insulated: XLPE

Inner Jacket: PVC

Outer Jacket: PVC

Maximum operating temperature: 90°C

Application:

As 600 volt Type MC cable rated 90oC in wet or dry locations; for install- ation aerially, in metal rack, trough, cable tray, or direct buried; for power and control circuits not exceeding 600 volts in manufacturing and process- ing plants, substations and generating stations. May be used in NEC Class l and ll, Div. 2 and Class lll, Div. 1 and 2 hazardous locations.

Standaars:

1.Listed by UL as Type MC cable per Standard 1569.

2.Individual conductors UL listed as Type XHHW-2 per UL Standard 44.

3.Jackets UL listed as Sunlight Resistant.

4.Cables UL listed for Direct Burial.

5.Cables pass UL and IEEE-383 ribbon burner flame tests and are UL listed For CT Use.

6.Cables pass IEEE-1202/CSA FT4 (70,000 BTU/hr) cable tray flame test.

7.Cables conform to ICEA S-95-658, NEMA WC70 for Nonshielded Power Cables Rated 2000 Volts or Less.

Construction:

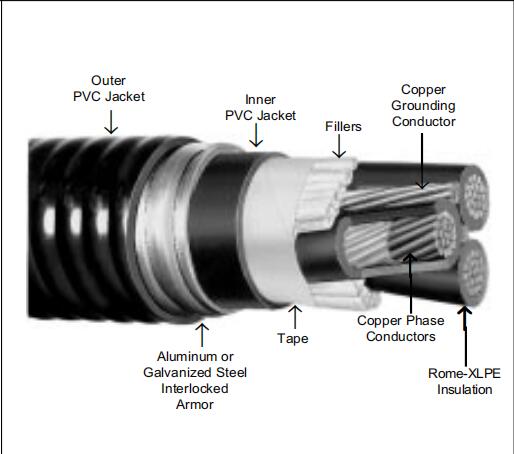

Three conductors of stranded uncoated copper, Rome-XLPE (crosslinked polyethylene) insulation, surface print phase identification, twisted with one uncoated copper grounding conductor, suitable fillers, binder tape, PVC inner jacket, aluminum or galvanized

- Scope:

This specification describes three conductor Rome-XLPE (thermosetting crosslinked polyethylene) insulated, aluminum or galvanized steel interlocked armor Type MC power cable having PVC jackets under and over the armor for use in circuits not exceeding 600 volts phase-to-phase at conductor temperatures of 90oC in wet or dry locations for normal operation, 130oC for emergency overload conditions and 250oC for short circuit conditions. Cables are intended for installation indoors or outdoors, aerially, in metal rack, trough or cable trays, or for direct burial. - Standards:

The following standards shall form a part of this specification to the extent specified herein:

UL Standard 1569 for Type MC cable.

UL Standard 44 for Type XHHW-2 conductors.

ICEA Pub. No. S-95-658, NEMA Pub. No. WC70 for Nonshielded Power Cables Rated 2000 Volts or Less. - Conductors:

Class B stranded annealed uncoated copper per Part 2 of ICEA. - Separator:

A suitable separator over the conductor may be used at the option of the manufacturer. - Insulation:

Shall be Rome-XLPE crosslinked polyethylene meeting the requirements of ICEA Table 3-7, Type X-2 and Type XHHW-2 requirements of UL 44. Average thickness of insulation shall be as specified in UL 44 for Type XHHW-2 conductors and in Table 3-4, Column B of ICEA. Minimum thickness at any point shall be not less than 90% of the specified average thickness. - Phase Identifacation:

Insulated phase conductors shall be printed with the numerals “1”, “2” and “3” on the surface of the insulation. - Assembly:

Three phase conductors shall be cabled together with a Class B stranded, uncoated copper grounding conductor and suitable nonhygroscopic fillers to make round. Length of lay shall not exceed 35 times the phase conductor diameter. The grounding conductor shall comply with the requirements of UL Standard 1569. A suitable non- hygroscopic cable tape shall be applied over the assembly. - Inner PVC Jecket:

Shall be PVC meeting the requirements of ICEA Table 4-1 and the Sunlight Resistant requirements of UL 1569. Average jacket thickness shall be in accordance with UL 1569. Minimum thickness at any point shall be not less than 70% of the specified average thickness. - Armor:

Aluminum or galvanized steel interlocked armor shall be applied over the inner PVC jacket. Armor shall be in accordance with UL requirements for Type MC cable and Paragraph 4.3.3 of ICEA. - Outer PVC Jecket:

Shall be PVC meeting the requirements of ICEA Table 4-1 and the Sunlight Resistant requirements of UL 1569. Average jacket thickness shall be in accordance with UL 1569. Minimum thickness at any point shall be not less than 70% of the specified average thickness. - Identifacation:

An ink print legend shall be applied to the surface of the PVC outer jacket providing cable and manufacturer identification. - Tests:

Conductors and completed cables shall be tested in accordance with UL requirements for Type MC cables having XHHW-2 conductors.

AMPACITY in accordance with the National Electrical Code for cables installed in uncovered cable tray without maintained spacing, at the conductor temperature indicated, in wet or dry locations, 30oC ambient temperature.